0102030405

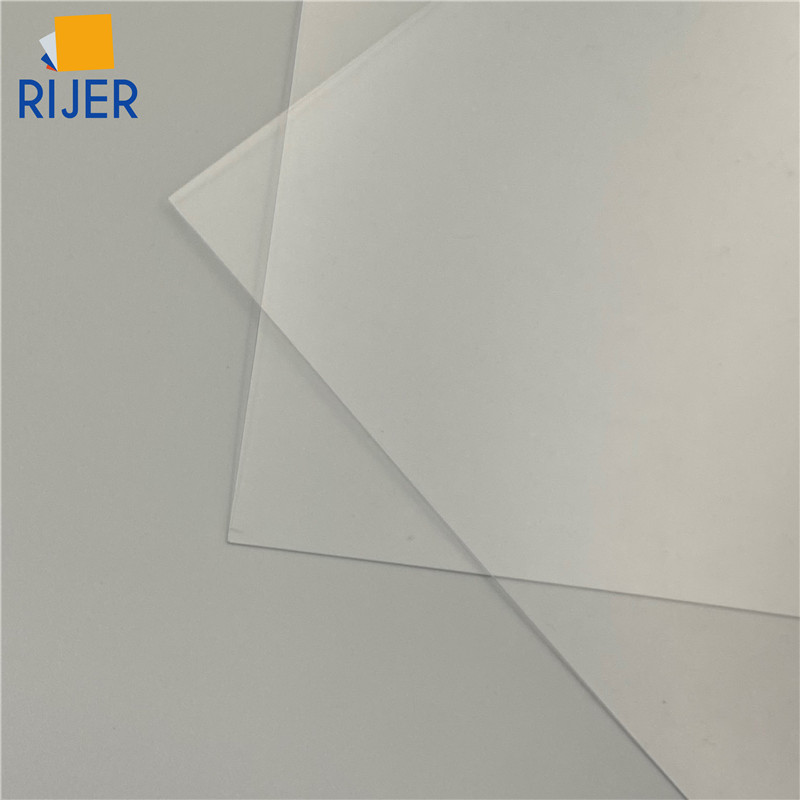

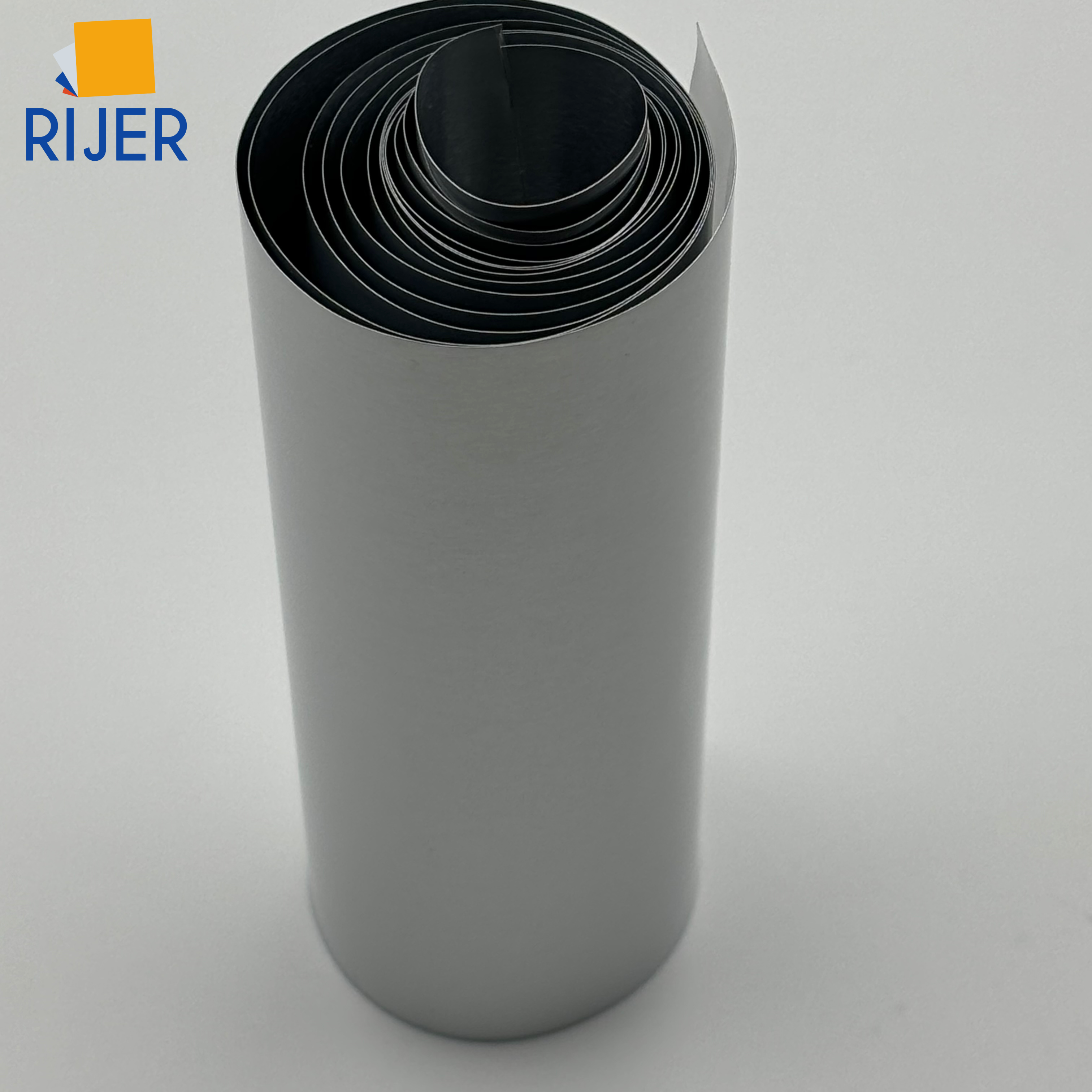

Silicone Coating Pet Release Film Manufacturing Silicone Coating Pet Release Base Film Material

Specification

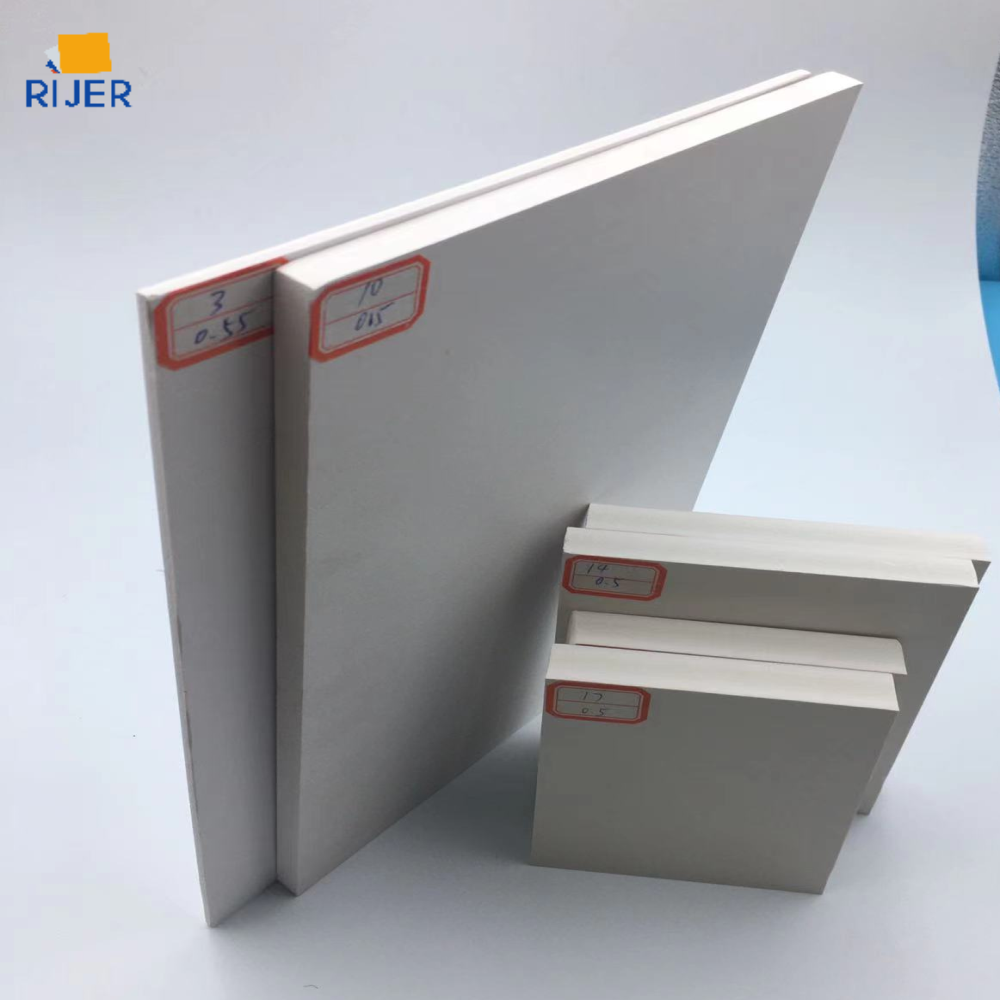

Release force: 1-3g/inch,3-5g/inch,5-10g/inch,10-30g/inch,30-50g/inch, max.200g/inch

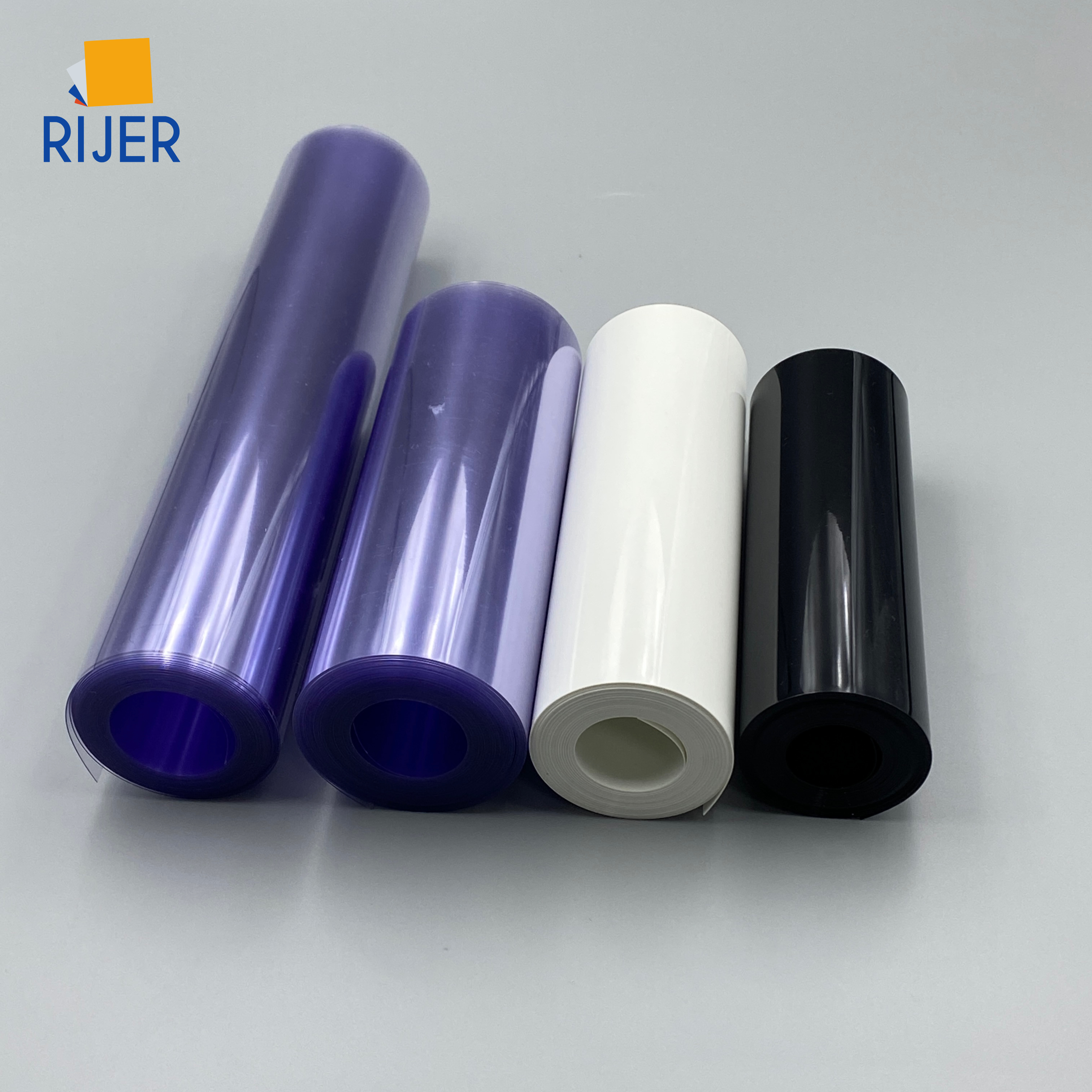

Color : Blue/Red/White/Green/Transparent

Thickness: 25~200um

Width: 30mm-2500mm

Inner Core diameter : 3 inch to 6 inch

Main Characteristics

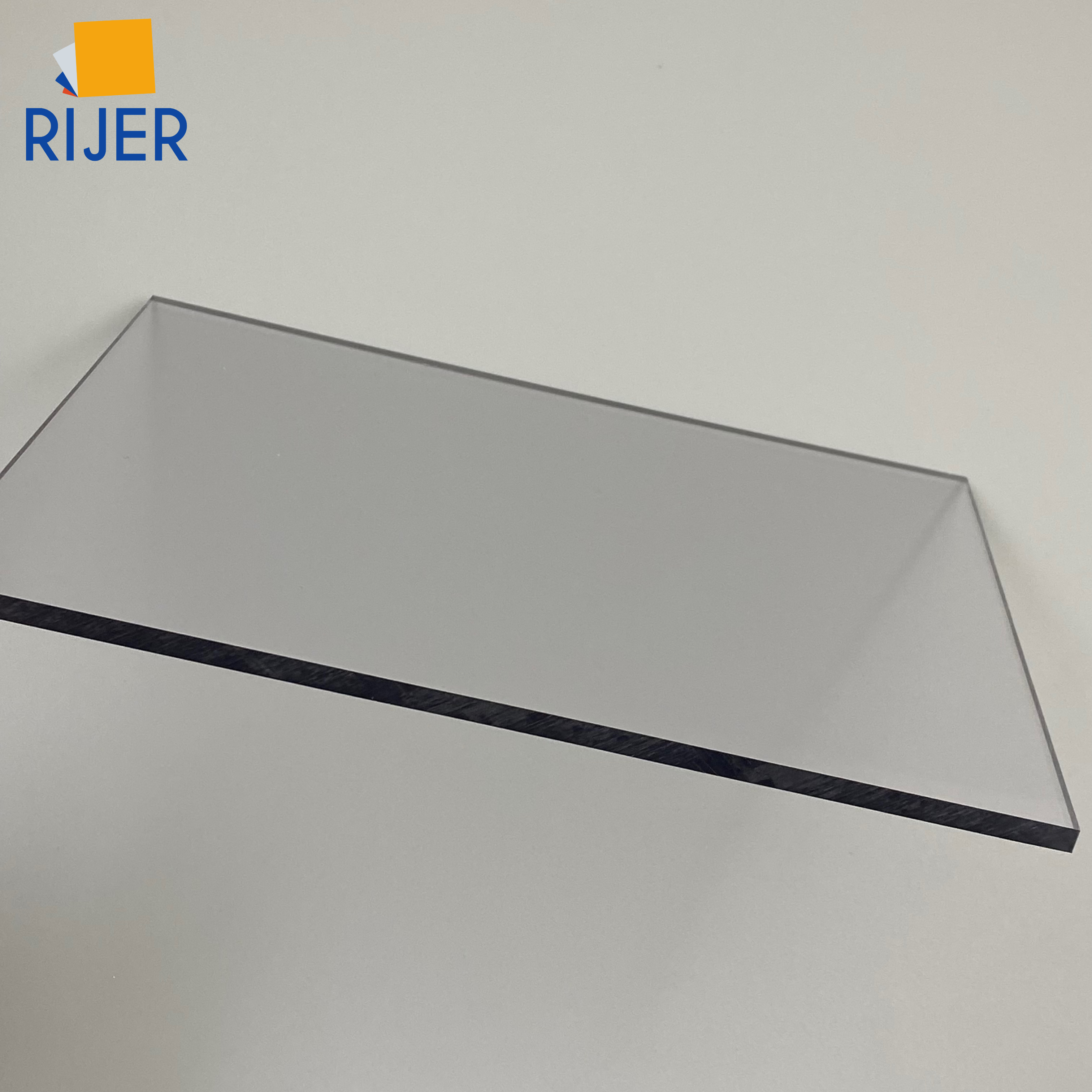

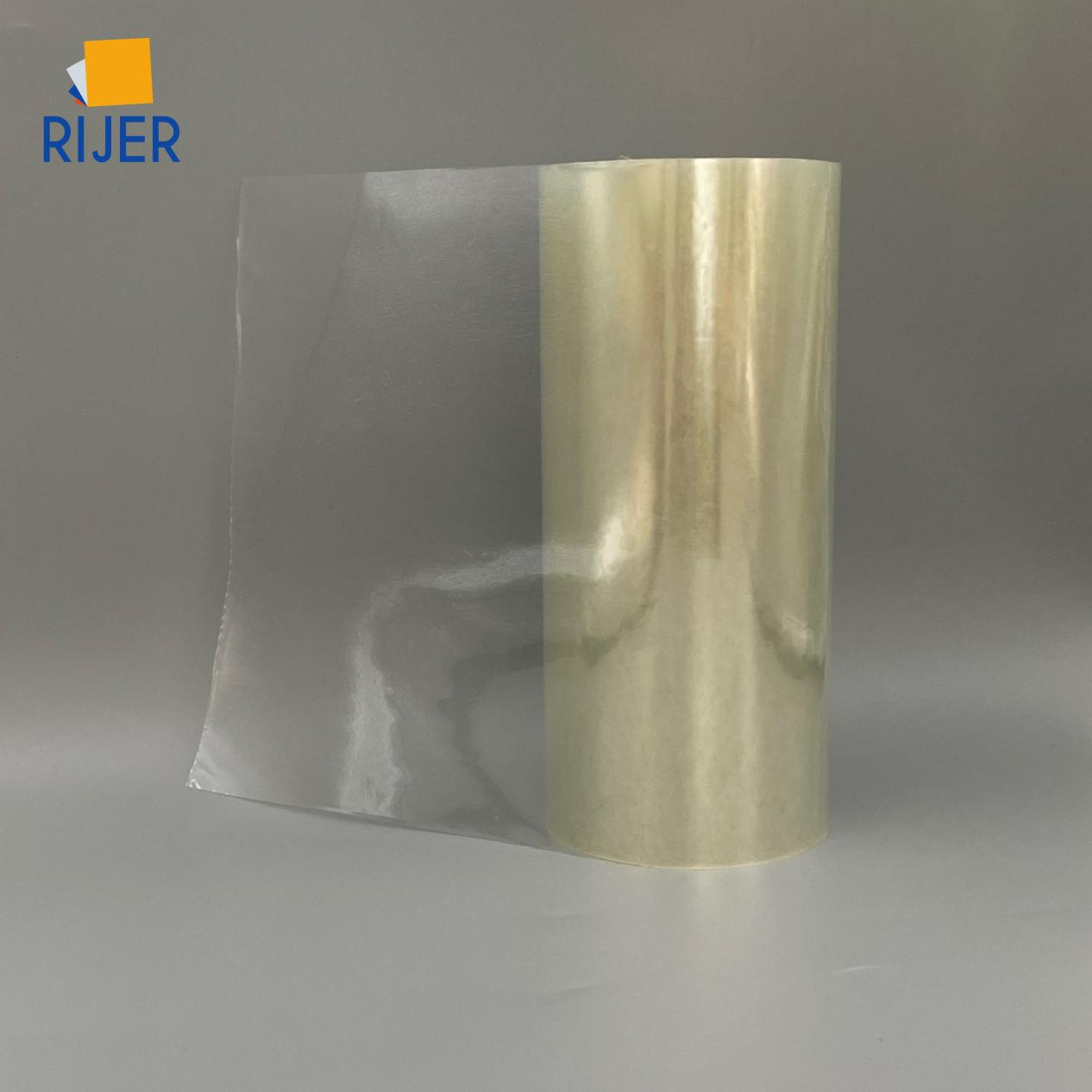

1.PET release film with a flat bright surface, high cleanliness, no cockle, grain, air bubble, pinhole, scratch and color lines.

2. PET release film has excellent physical and mechanical properties, little thickness tolerance, even transparency , low hot-shrinkage rate, good tensile strength.

3. PET release film surface release matter coating uniform ,little release force run-out tolerance,high SAS.

4. PET release film can be cut into roll or disk, has little dependence on storage temperature,storage humidity, storage time.

description2

Applications

1.Electronic die cutting, adhesive products, coated compound.

2.Medicine, cars, construction, furniture

3.Sealing material, laser anti-counterfeiting, packaging, printing

4.Carbon fiber products, reflective materials, waterproof materials, etc

Storage condition and Shelf time

* Away from direct sunlight,under the condition of normal temperature and 20%-80% RH;

* Shelf-time is within 6 months from production date.

APET sheet

APET sheet